Last Updated on May 9, 2025 by Jim C.

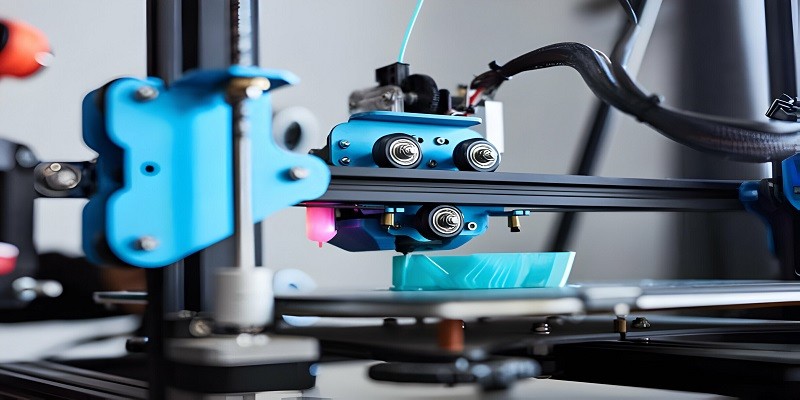

3D printing revolutionizes manufacturing, medicine, and more due to its transformative capabilities and limitless applications. This technology enables the creation of three-dimensional objects from digital designs, making it a game-changer for various industries.

From rapid prototyping in manufacturing to personalized medical devices and even the construction of homes, 3D printing has opened up new possibilities for innovation and customization. Its ability to produce complex shapes and intricate details with ease has significantly reduced production costs and time.

As a result, this technology is reshaping the world of manufacturing, medicine, art, and beyond, paving the way for a future where the only limit is our imagination.

The Evolution Of 3d Printing

Discover the remarkable journey of 3D printing, a technology that has transformed industries and revolutionized the way we create objects. Let’s delve into the fascinating evolution of this groundbreaking innovation.

Origins And Early Development

In the beginnings, 3D printing emerged as a method for rapid prototyping in the 1980s.

An engineer named Charles Hull pioneered the first 3D printing process using a technique called stereolithography.

This process involved creating 3D objects layer by layer from a digital design, sparking the birth of additive manufacturing.

Advancements In 3d Printing Technology

As technology progressed, so did 3D printing, paving the way for new horizons in various fields.

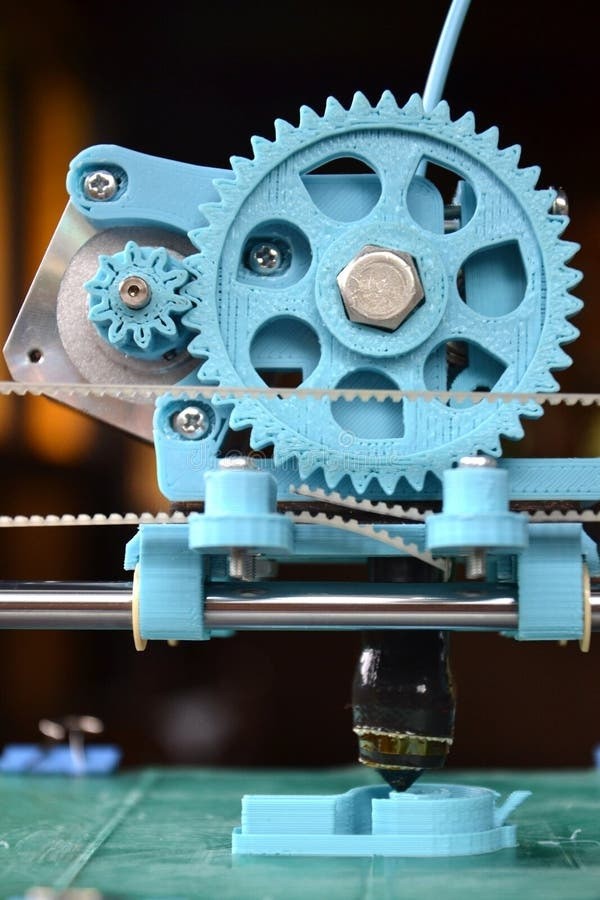

The innovations in materials and printing techniques have enabled the production of highly complex structures.

Today, 3D printing is utilized in diverse industries, from aerospace to healthcare, showcasing its vast capabilities.

3d Printing In Manufacturing

3D printing, also known as additive manufacturing, has revolutionized various industries, including manufacturing. Its impact on prototyping and product development, as well as customization and complex designs, has been nothing short of remarkable.

Impact On Prototyping And Product Development

3D printing has significantly transformed the prototyping and product development process in manufacturing. In the past, creating prototypes and testing new designs meant going through lengthy and costly traditional manufacturing methods.

- With 3D printing technology, manufacturers can now rapidly produce prototypes in-house.

- This allows them to iterate and refine designs more quickly, reducing time to market.

- Design modifications can be easily made without the need for expensive tooling or starting from scratch.

- Product developers can test different iterations, identify flaws, and make improvements in a more cost-effective and efficient manner.

The ability to swiftly prototype and iterate helps manufacturers save time and costs while enabling them to bring products to market faster than ever before.

Customization And Complex Designs

One of the significant advantages of 3D printing in manufacturing is the ability to produce highly customized and complex designs that were previously challenging or impossible to achieve with traditional manufacturing methods.

- 3D printing allows for intricate geometries, enabling the creation of complex parts and components with ease.

- Complex structures, such as lattices and organic shapes, can be printed more accurately, providing greater design freedom.

- Customization is made easier as individualized products can be created without the need for additional tooling.

- Manufacturers can respond to individual customer demands and produce personalized products on a larger scale.

This level of customization and the ability to produce intricate designs have opened up new possibilities in manufacturing across various industries, including aerospace, healthcare, and automotive.

3d Printing In Medicine

The advancements in 3D printing technology have opened up a world of possibilities in the field of medicine. From bioprinting and tissue engineering to prosthetics and medical devices, this innovative technology is revolutionizing the way we approach healthcare.

Bioprinting And Tissue Engineering

One of the most remarkable applications of 3D printing in medicine is bioprinting. With this technology, scientists and researchers have the ability to create 3D structures using biological materials such as living cells. This not only allows for the creation of artificial organs and tissues but also provides a platform for drug testing and personalized medicine.

Prosthetics And Medical Devices

3D printing has made significant advancements in the field of prosthetics and medical devices. Traditionally, the process of creating prosthetics was time-consuming and expensive. However, with 3D printing, the production of prosthetics has become faster, more cost-effective, and customizable to fit the individual needs of patients.

Additionally, medical devices such as implants, surgical instruments, and hearing aids can now be produced using 3D printing technology. This not only speeds up the manufacturing process but also allows for precise customization, resulting in better patient outcomes.

- Advantages of 3D printing in medicine:

- Reduced manufacturing time and cost

- Customization for patient-specific needs

- Improved efficiency in drug testing and development

- Enhanced surgical planning and training

- Increased accessibility to prosthetics and medical devices

3D printing has immense potential in the field of medicine. From bioprinting and tissue engineering to prosthetics and medical devices, this technology is transforming healthcare and improving patient outcomes. With continued advancements, we can expect to see even more groundbreaking applications in the future.

Future Applications Of 3d Printing

The potential of 3D printing technology is immense, and it continues to expand into various industries. Here are some exciting future applications of 3D printing, showcasing its versatility and impact.

Space Exploration And Aerospace

In the realm of space exploration and aerospace, 3D printing has the potential to revolutionize the way space missions are conducted. The technology allows for the creation of intricate components, such as rocket parts and satellites, with lightweight and durable materials. This could significantly reduce the cost of space exploration and enable the development of more efficient and advanced spacecraft.

Construction And Architecture

3D printing holds the promise of transforming the construction and architecture industries. With this technology, it becomes possible to fabricate complex building structures and components rapidly and with great precision. This could lead to more efficient construction processes, sustainable housing solutions, and innovative architectural designs.

Frequently Asked Questions

What Is 3d Printing And Its Applications?

3D printing is a process of creating three-dimensional objects from digital models. It is used in manufacturing, medicine, architecture, and more.

How Does 3d Printing Revolutionize Manufacturing?

3D printing streamlines prototyping, reduces tooling costs, and enables on-demand production, transforming the manufacturing industry.

What Are The Medical Applications Of 3d Printing?

3D printing is utilized in creating patient-specific prosthetics, implants, surgical models, and drug delivery systems in the medical field.

Can 3d Printing Benefit The Aerospace Industry?

Yes, 3D printing enhances design freedom, reduces weight, and allows the creation of complex geometries, revolutionizing aerospace manufacturing.

How Does 3d Printing Contribute To Sustainability?

3D printing minimizes material waste, energy consumption, and transportation emissions, promoting sustainable manufacturing practices.

Conclusion

Innovating industries and enhancing healthcare with 3D printing technology is reshaping the future. Its versatility and precision offer limitless potential for creativity and efficiency. Embracing this transformative tool is key to driving progress and unlocking endless possibilities in various sectors.

The 3D printing revolution is here to stay.